Current Research Activities

Printable Materials Laboratory Analysis (Funded by AMRDEC)

Fast Detection and Analysis of Defects in Composite Missile Structures Using Laser Scanning Techniques.

Nano-Reinforcement Effects on Damping Properties of Composite Structures under Thermal and Cryogenic Environments.

Design Optimization of bolted joints of Graphite/Epoxy composites under Fatigue Loading.

Research Facilities

Experimental Mechanics Lab:

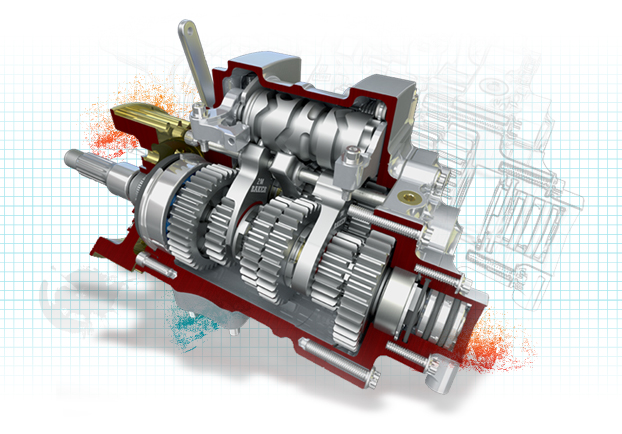

CAD/CAE Lab:

Advanced Testing and Evaluation Lab:

Laser Scanning and Measurement Lab:

Advanced Manufacturing Lab:

Research Areas and Research Projects

Dr. Mohamed Seif

a) Laser Scanning and Measurement

3-D laser imaging for cervical spine motion analysis (Funded by National Institute of Health – NIH))

Fast Detection and Analysis of Defects in Composite Missile Structures Using Laser Scanning Techniques (Funded by Missile Defense Agency - MDA)

Health Monitoring, Failure Analysis and Damage Assessment of Aerospace and Advanced Structures (Funded by DOD - Army Research Office)

Deformation, strain, and temperature fields in sliding contact (Funded by National Science Foundation – NSF)

Fast detection of flaws by Electronic Shearography (Funded by National Science Foundation – NSF)

Deformation and warping in magnetic taps (Funded by 3M Company)

Identification of Surface and Near Surface Defects and Damage Evaluation by Laser Speckle Techniques (Funded by NASA- HQ)

Determining seam disbonds in deicing mechanisms (Funded by NASA - Langley)

Development of a 3-D Laser Imaging Technique for Biomedical, Microbiology, Micro-Electro-Mechanical Systems, and Damage Assessment Applications (Funded by NIU - Illinois)

Residual stresses in plastic and ceramic/ceramic composite pipes

Mixed mode failure in graphite/epoxy composites

Warping strain in thin sheets under internal pressure and tensile loading

In situ measurement of plastic deformation at crack tips

b) CAD/CAM/CAE and Design Optimization

Total design and Product Realization Project (PRP), funded by NSF

Dynamic analysis and design considerations for conveyor mechanisms, FMC Corporation, Airline Equipment Division, Orlando, FL

Optimizing the performance of the Crimping Mechanism for Daniels Manufacturing Corporation, DMC, Orlando, FL

CAD/CAE and optimization techniques in machine design

Geometric Dimensioning and Tolerancing optimization for product and process design

Design for assembly and manufacturing

Developed design procedures for optimizing journal-bearing performance

Experience in working with rapid prototyping, CNC, and EDM machines

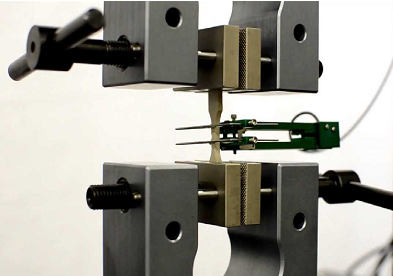

Designing cost efficient bench-top testing devices

Designed a multipurpose tribotester apparatus to investigate the effect of different variables on sliding contact problem

Designed a fast response loading mechanism that provides an easily varying contact stiffness

Design and manufacturing of steady damped stationary devices to eliminate vibrations associated with heavy duty deep drilling operations

Developed four multimedia design case studies as teaching modules

c) Testing and Evaluation of Advanced Composites

Fast Detection and Analysis of Defects in Composite Missile Structures Using Laser Scanning Techniques (Funded by Missile Defense Agency - MDA)

Health Monitoring, Failure Analysis and Damage Assessment of Aerospace and Advanced Structures (Funded by DOD - Army Research Office)

Nano-Reinforcement Effects on Damping Properties of Composite Structures under Thermal and Cryogenic Environments (Funded by National Science Foundation – NSF).

Printable Materials Laboratory Analysis (Funded by US Army - AMRDEC)

Residual Stress Measurements in CFRE and GFRE Composite Missile Shells (Funded by US Army - AMRDEC)

Design Optimization of bolted joints of Graphite/Epoxy composites under Fatigue Loading

Mixed mode failure in graphite/epoxy composites

d) Additive Manufacturing and Reverse Engineering

Printable Materials Laboratory Analysis (Funded by US Army - AMRDEC)

Integrate RF and electronics into additive manufacturing products to reduce size, weight and cost of these modules (Funded by US Army - AMRDEC)

Study the thermomechanical properties of PLA, HIPS and ABS filaments

Design optimization of the 3D printing process for improved In-Plane shear and cross-section shear stress

Investigate the thermomechanical properties across 3D printed layers

Optimize the material properties and functionality in Additive Manufacturing

Minimize failure stresses using Design optimization of part orientation

Investigate the dynamic and fatigue properties of 3D-Printer parts

e) Mechatronics and Industrial Automation

i. Developed Projects

Implementation of Behavior Based Artificial Intelligence in Miniature Mobile Robots

A Bench Top Microprocessor Based Testing Device

X-Y Micropositioning Devices

Candy-tronics: A Microprocessor Based Vending Machine

A Dynamic Balancing Device for Rotating Shafts

A Microprocessor Based Elevator Module

Automated Programmable Train Set

Real Time Data Acquisition System

In Situ Object Tracing in Plane Motion

I/O Box for laboratory development projects

Thermal Control Unit

A Computer Controlled Polar Plotter

Infrared Remote Control of a Stepper Motor

Interfacing with a Precision Navigation Vector 2X Compass Module

Implementation of Multi-Tasking, Transition Logic, and Fuzzy Logic

Timed Operation for Control and Operator Interface

Radio Frequency Remote Control

Range Detection using Sonar Sensor

ii. Lab Modules

Computer Control of Unipolar Stepper Motor

Computer Control of Bipolar Stepper Motor and Building its driver circuit

Computer Interfacing of 7-Segment LED Display

Microprocessor Controlled Digital Combination Lock (Digital Input Ports)

Construction of an 8-bit Analog to Digital Converter Circuit for Data Acquisition

Acquisition of Temperature Data Using a Thermistor

Velocity Control of DC Motors

Motor-encoder Feedback Control

Temperature Control Using MELIOR Thermoelectric Modules.

I/O Box for laboratory development projects

Light Patterns Using Digital Output Ports

Interfacing with Optrex LCD Panels

Controlling multiple devices